In today’s highly competitive market, even the smallest details can make a monumental difference in how your brand is perceived. One such detail—often overlooked—is the humble hat button. From streetwear to luxury fashion, custom hat buttons have evolved from simple fasteners to powerful brand identifiers. If you're looking to elevate your brand’s visual language, ordering directly from manufacturers offers unmatched advantages in quality, customization, and cost-efficiency.

From Streetwear to Signature Style: The Rise of the Hat Button as a Brand Icon

Modern brands are increasingly aware that differentiation lies not only in product quality or marketing campaigns but also in the finer details. The hat button—once a purely functional piece—has become a canvas for storytelling. Whether it’s a minimalist metallic emblem or a colorful enamel badge, the design of a hat button can silently communicate your brand’s personality, values, and aesthetic.

Fashion houses and indie labels alike have embraced this subtle yet impactful branding opportunity. Think of a baseball cap with a subtly embossed logo on the button, or an outdoor brand using recycled materials in their fasteners to align with sustainability values. These are not just embellishments; they are extensions of brand identity.

Inside the Workshop: How Custom Hat Buttons Are Made

Behind every polished hat button is a meticulous manufacturing process that blends craftsmanship with technology. Starting with a design concept, manufacturers use precision tools to shape, mold, and finish each button to meet exact specifications. Whether you choose brass, zinc alloy, plastic, or fabric-covered styles, each material brings its own unique texture and durability.

Modern factories are equipped with advanced techniques like laser engraving, screen printing, and 3D modeling to ensure that even the most intricate designs come to life with clarity. More importantly, they can handle both small-batch samples and large-scale production runs, offering flexibility that suits both emerging and established brands.

Why Cutting Out the Middleman Makes Sense

While it may seem convenient to go through a third-party supplier, doing so often introduces unnecessary costs and communication barriers. Middlemen typically mark up prices significantly—sometimes by as much as 50% or more—without adding any real value to the product. Worse, they can act as a filter that distorts your brand’s vision, leading to misinterpretations in design or quality.

By working directly with manufacturers, you gain full transparency over the production timeline, material selection, and design adjustments. This direct line of communication ensures that your brand’s voice is preserved throughout the process. It also allows for faster turnaround times and the ability to troubleshoot issues before they escalate into costly mistakes.

The Power of a Sample: Avoiding Costly Mistakes Before Production

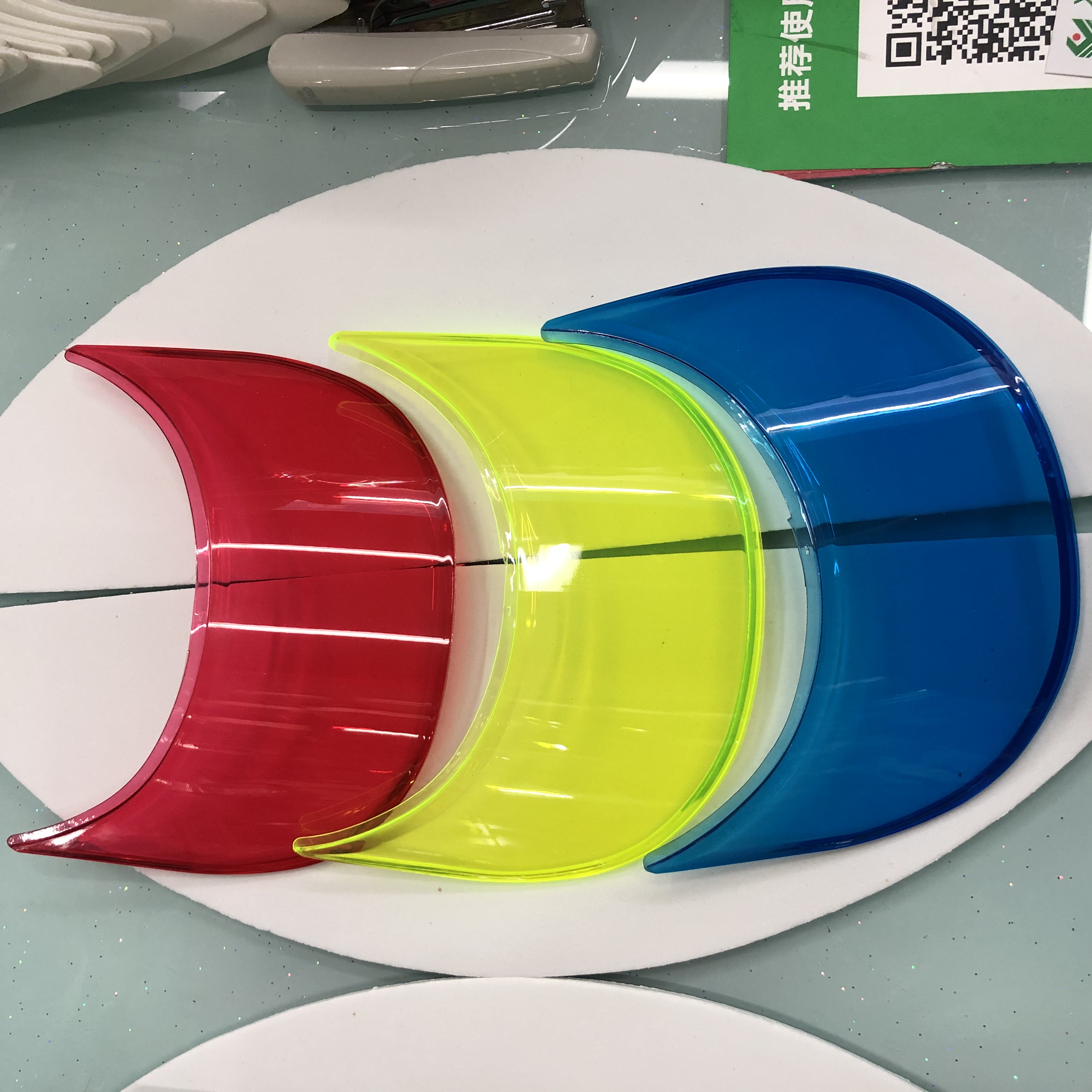

Before placing a large order, requesting a sample is one of the smartest steps you can take. A physical sample allows you to evaluate the color accuracy, material quality, and overall finish of your custom hat buttons. It also gives you the chance to test the button’s durability under real-world conditions—like repeated washing or exposure to the elements.

A reputable manufacturer will walk you through this process, offering revisions until the sample meets your expectations. This stage is crucial not only for quality assurance but also for building trust. When you receive a sample that aligns with your vision, you gain confidence in the manufacturer’s ability to deliver at scale.

Customization Beyond Imagination: Telling Your Brand’s Story

From logos to slogans, textures to color gradients, the possibilities for personalization are nearly endless. Whether you're launching a limited-edition collection or creating merchandise for a major event, custom hat buttons offer a unique way to reinforce your brand message.

Sports brands might opt for bold, high-contrast designs that reflect energy and movement, while luxury fashion labels might lean toward sleek, minimalist buttons with subtle metallic finishes. Even eco-conscious brands can integrate recycled materials or biodegradable components into their designs, aligning their values with their visual identity.

Take inspiration from brands that have successfully used hat buttons to stand out. One outdoor apparel company, for instance, used a custom button shaped like a mountain peak to symbolize adventure and resilience. It quickly became a signature element of their brand, recognized and appreciated by loyal customers.

Balancing Budget and Quality: The Economics of Bulk Customization

Many brands hesitate to go custom due to perceived cost barriers. However, ordering in bulk can significantly reduce the per-unit price of custom hat buttons. Manufacturers often offer tiered pricing, meaning the more you order, the more you save. For startups and growing businesses, this presents a golden opportunity to maintain premium branding without breaking the bank.

Establishing a long-term relationship with a trusted manufacturer can unlock even more value. Repeat orders often qualify for loyalty discounts, priority production slots, and personalized support. With careful planning and strategic ordering, custom hat buttons can become a cost-effective tool for brand differentiation.

Looking Ahead: Sustainability and Innovation in Hat Button Design

As consumers become more environmentally conscious, sustainable practices are no longer optional—they're expected. Forward-thinking manufacturers are responding by introducing eco-friendly materials like recycled metals, plant-based resins, and compostable plastics into their product lines.

By choosing a manufacturer that prioritizes green initiatives, your brand can demonstrate a commitment to environmental responsibility. This not only appeals to eco-conscious customers but also positions your brand as a leader in ethical fashion. The future of customization is green, and early adopters will reap the rewards in terms of customer loyalty and market positioning.

Are You Ready to Go Direct?

Before reaching out to a manufacturer, it's essential to prepare your brand assets and expectations. Have your logo files, color codes, and design sketches ready. Clearly define your target quantity, timeline, and budget. Most importantly, research potential manufacturers thoroughly—read reviews, ask for references, and verify certifications if sustainability is a priority.

Building a strong partnership with your manufacturer is key to long-term success. Clear communication, mutual respect, and shared goals will ensure that your brand’s vision is consistently translated into high-quality products. Whether you're launching a new collection or refreshing your existing lineup, direct sourcing is the smart, scalable way to go.